|

Representing some of our most common workload is the testing conducted in our Materials & Standards Labs. These two connected rooms house the majority of our materials testing capabilities. The rooms are kept at standard conditions (23 °C / 50% Relative Humidity) at all times in order to maintain a proper test and storage environment. The equipment in these labs provided, the capability to test or evaluate the materials for which PSCC has lead activity responsibility as listed in Chapter 6 of AR 700-15, Packaging of Materiel. As such, PSCC can test: tapes, adhesives, barrier materials, preservation materials, desiccant materials, as well as marking and labeling materials. In addition, PSCC also can test and evaluate the characteristics of materials associated with fiberboard boxes/sheet stock, wood & wire-bound boxes, non-metal pallets, bags/sacks, tags, document protectors, and packing lists. |

|

Materials Lab

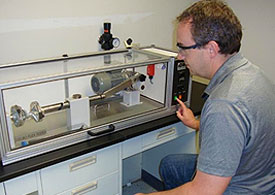

Although both labs are equipped for handling and testing various materials, our materials lab is geared more towards those tests involving chemical properties and exposure. The lab is equipped with all of the necessary hardware and safety equipment for subjecting materials to tests such as water vapor transmission (permeation), viscosity, stiffness, corrosion resistance (VCI protection) and pH analysis. As with our other facilities, the materials lab also has temperature and humidity exposure capabilities.

|

|

Standard Conditioning Room

The adjoining Standard Lab, contains those pieces of equipment most suited to testing the physical properties of materials. This is where we conduct tension/elongation and compression tests for items which are exposed to forces which may degrade or remove container labels and hardware. We also evaluate the properties of fiberboard/sheet stock, wood, plastics, barrier materials, and labels. Examples of testing include; abrasion, Mullen burst, Elmendorf tear, beach-type puncture, edge crush, adhesion (for tapes, labels, etc.), print contrast, seal/seam integrity, flexibility, and water resistance (Cobb).

In accordance with the applicable test methods, many of the tests listed above are conducted after aging, or after undergoing environmental exposure and/or rough handling.

|